Papermaking

Paper as we know it today originated in China. In the year 105 T’sai Lun, a court official, experimented with materials in a  search to create a lightweight but strong surface for writing. He macerated the fibres of mulberry and bamboo plants, then mixed the fibres with water in a large vat.

search to create a lightweight but strong surface for writing. He macerated the fibres of mulberry and bamboo plants, then mixed the fibres with water in a large vat.

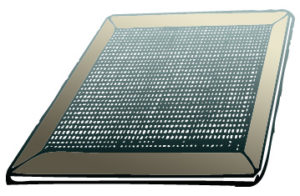

A screen was dipped into the vat and lifted, catching the fibres on its surface. When dried, this thin layer of intertwined fibre became what today we call paper.

By the 6th century, the art of papermaking had spread to Vietnam, Tibet, Korea, and Japan. It travelled westward, with the Moors introducing papermaking into Europe in the 11th century.

The traditional Japanese process of papermaking continues today and is described by the Awagami Factory, see Awa Washi: Preparation and Process. The fibres of plant material are softened by soaking in water and boiling, then cleaned and sieved.  The fibres are beaten to separate the individual filaments, and the resulting pulp, the stock, is dispersed in water in vats. The stock is scooped up on screens to form the sheets of paper; the screens may incorporate a watermark. The wet sheets of paper are laid onto absorbent felt couches.

The fibres are beaten to separate the individual filaments, and the resulting pulp, the stock, is dispersed in water in vats. The stock is scooped up on screens to form the sheets of paper; the screens may incorporate a watermark. The wet sheets of paper are laid onto absorbent felt couches.

Layers of paper between couches are pressed to remove the water and consolidate the paper. The damp sheets of paper are removed from the press and taken to drying racks. Paper may be treated with size to enhance certain characteristics, or it may be coloured with dye.

Aside from additives, the fundamental character and quality of hand-made paper is largely determined by the type of fibre used and the skill of the papermaker when handling the screen.

Paper can also be made from the fibres in rags and cotton is often still used in fine art papers. Most industrially made paper today uses wood pulp. The basics of papermaking are essentially the same today as in the past, but industrial production is mechanised and refined by the use of chemicals. Skilled operatives are still required to inspect the quality of each part of the process.

Papermaking machinery

Modern papermaking began in the early 1800s in Europe with the acceleration of the pulping process, using the Hollander rag-beating engine in the place of stamping machines. This led to the development of machines that produce a continuous roll of paper rather than individual sheets, which hugely accelerated the rate of production.

A continuous papermaking machine was invented by the Frenchman, Nicolas Louis Robert in 1798. In England, Sealy and Henry Fourdrinier financed the further development of the machine by Brian Donkin. The first machine was installed at Frogmore Mill, Apsley, Hertfordshire, in 1803, see Frogmore Mill. The process of placing the stock on a continuously moving wire rather than individual screens, was the innovation that made today’s high speed paper machines possible.

A papermaking machine comprises:

Forming section The machine forms the paper by depositing the stock onto a moving continuous screen, or wire. It is passed under a dandy roll that breaks up lumps of fibre and may incorporate a watermark. Some of the water drains off and some is sucked out. At the end of the wire, the stock is picked off by a felt couch roll which is moving at the same speed.

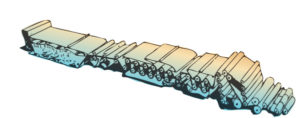

Press section It is then passed through pairs of press section rollers, removing more of the water.

Dryer section The paper then moves through the heated cylinders of the dryer section. It may have been internally sized as part of the wet process or passed through a size press within the dryer section, or both. Some machines incorporate a coater to coat papers with calcium carbonate or china clay to produce a very smooth, bright surface.

Finishing section The dried paper is smoothed by calendar rollers and then wound on drums prior to cutting.

Continuous technical improvement has produced modern paper machines which are computer controlled to produce paper to exacting standards at high speed. Modern conversion plants precision cut, electronically check, and automatically pack the paper.

A detailed description of industrialised papermaking is in preparation for the launch of the Penicuik Museum and Papermaking Heritage Centre.

For a very brief history of papermaking, take a look at a 10 minute talk we gave to Penicuik High School